You will

do an exercise of modeling a 3d model in CREO and

print it.

The sum of dimensions of length, width and height is

not to exceed 90 mm (e.g. length 30, width 30,

height 30)

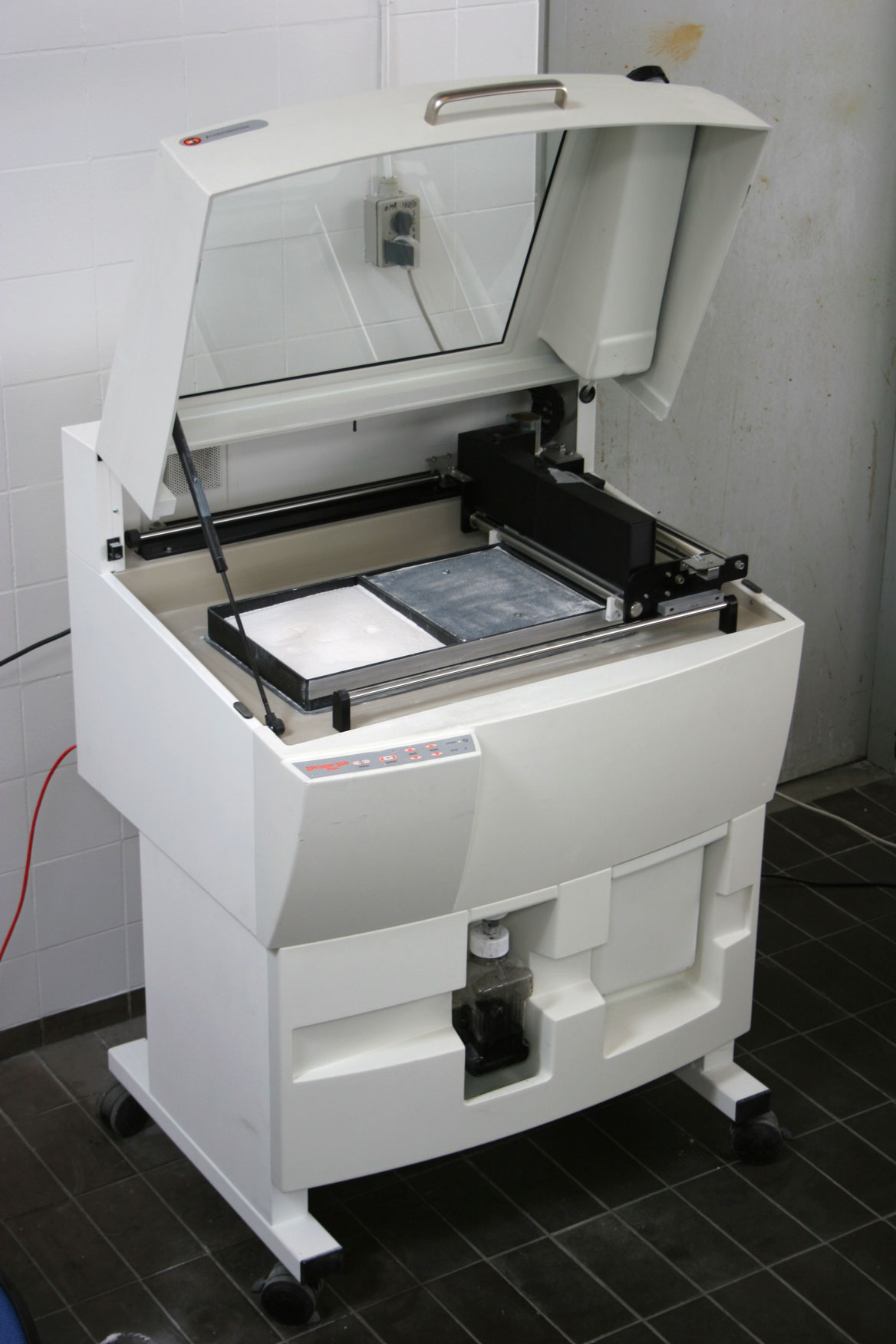

Your model will be printed on our plaster printer

Plaster printer characteristics:

The

model is made within a dune of plaster powder,

meaning that support structures are not necessary.

Closed voids are to be made with ”draining holes” to

avoid entrapment of powder.

Wall thickness is to be no thinner than 1,5 mm.

Plaster models are typically used for viewing

purposes due to a good surface quality and little

mechanic strength. The surface strength can improved

with paint, lacquer, wax or epoxy.

Translation to .stl format:

Inside

CREO the model is to be translated to the .stl

format used by both printers. The stl translation

generates a triangulated facet surface model. You

should be conscious of defining the size of the

triangles and the angle between them in such a way,

that the model looks nice and is well defined and at

the same time has a moderate .stl file size. There

is no need for a model with a surface tolerance much

finer than the tolerance of the printer. You should

experiment with various combinations of triangle

sizes and angles.

The link below opens a Quicktime movie describing file translation from Creo to 3ds Design, but the process is the same. Look what happens between 00: 29 to 00: 55

Export from Creo to 3ds Max design using .stl format

www.polynet.dk/rpt - Info on rapid prototyping exercises, case studies, previous projects gallery etc.