|

1.

INSPECTING THE MODEL

To start

with I look at the model to find problem areas and to get a general overview

of the model. I look for:

- parallel

sides that could be used for clamping

- internal

corners that should be (if possible!) sharp

- rounds

and other surfaces that are not parallel or normal to any of the major

planes (xy, zx & zy). These will require surface milling with a

ball mill

- areas,

where uniform machining (same tool/same approach would be desirable

or most logical

|

| TOP:

Check

space and radius of rounds |

FRONT:

Small

space between front light and bumper |

| BACK:

Small

space between axle and flat bottom |

BOTTOM:

Small

space behind wheel |

| SIDE:

Small

space around wheel |

|

|

|

2.

PLANNING CLAMPING/OPERATIONS

The main

focus is on making clamping of the truck possible after each operation,

and to decide what to machine from where; there is always more than one

solution.

One way

to confront the clamping problem is to think forward to the last operation:

How will you clamp the truck when almost all of it is machined? What should

be the last operation? You need to have parallel planes/surfaces available.

In this case,

there are parallel planes available on the sides and the wheels. For a

last operation, either will do fine.

When placing

the Reference Machining Zero coordinate system, already machined surfaces

are optimal as references. This is utilized from Operation 3 onwards.

|

Chosen sequence

of operations (shown here with fixture suggestions):

|

OPERATION

1

Machining of the right side. The Reference Machine Zero, RMZ is

on top of the work piece, centered in x and y.

|

OPERATION

2

Machining of the left side. The location of the RMZ is the same

as on the right side, opposite side of workpiece of course

|

|

OPERATION

3

Machining of the bottom. The RMZ is on the bottom of the truck,

centered in x and y.

|

OPERATION

4

Machining license plate area in the back. The RMZ is on top of the

work piece, x is located on the bottom face of the truck

|

|

OPERATION

5

Machining the front. The RMZ is on top of the work piece, x is located

on the bottom face of the truck

|

OPERATION

6

Machining the rest from the top. The RMZ is on top of the work piece,

x and y is centered according to already machined surfaces on the

truck.

|

|

|

3.

STARTING A NEW MFG SESSION

OPERATION 1

The actual

CAM work starts. You retrieve the truck, create the workpiece and set

up the first operation, including fixture.

While it

is not absolutely necessary, it is a good idea to visualize the fixture.

It makes it easy to discuss this with the operator. Furthermore, you can

check whether there will be collision with the tool when doing the NC

Checks.

|

Click the

buttons to set up the fixture. The fixture will be a part on its own.

When sketching, reference the sides of the workpiece. If this changes,

the fixture will too.

|

|

4.

CREATING SEQUENCES

Take a look

at the NC Check video first. Underneath is described the sequences in

this operation.

Parameters

different from the default milling parameters are listed.

| OPERATION

1 |

| Sequence

1 - Volume Milling - 10 mm end mill |

| |

Parameters:

Scantype = type_spiral

Rough_option = rough_&_prof |

| Sequence

2 - Surface Milling - 4 mm ball mill |

| |

Window

finishing

Parameters:

Scallop_hght = 0.02

Lace_option = Line_connect

More

on these two important parameters below

|

| Sequence

3 - Surface Milling - 4 mm ball mill |

| |

back

wheel, cutline surface milling in a helical movement.

Parameters:

Scallop_hght = 0.02

Scan_type = type_helical |

| Sequence

4 - Surface Milling - 4 mm ball mill |

| |

front

wheel, same as Seq. 3 |

| Sequence

5 - Volume Milling - 2 mm end mill |

| |

Volume

above the wheels

Parameters:

Scantype = type_spiral

Rough_option = rough_&_prof |

|

WATCH VIDEO of OPERATION 1

|

1st

volume (seq. 1) shown in red

2nd

volume (seq. 5) shown in red

|

Notes:

The volume milling sequence (no. 1) removes material on the

sides and partly around the wheels. Surfaces parallel

or normal to the retract plane are finished (machined

to the measure). The volume, and therefore the milling, stops

at the backside of the wheels, as it is not machinable within

the current operation.

Notice that the volume extends beyond the boundaries of the

workpiece in the xy plane, to make sure the workpiece is completely

removed.

Rule of Thumb: This distance should be Tool diameter

+ 1

To make room for a surface finish of the window, this area is

included in the volume.

For

Operation 3 we need to clamp the truck with the bottom up, therefore

the workpiece is not machined in its entire width, see clamping

for Operation 3

The

second volume milling sequence (seq. 5) removes the material

above the wheels, where the bigger tools could not go. A new

volume is created for this sequence.

There is not much room here, so a 2 mm mill is the only choice.

Because of its limited length, the volume is no deeper than

the tool is capable of.

The remaining material can be further reduced in another

operation, but not entirely, and there will be difficulties

with strange tool overlaps. In

other words, and in this particular case - it is not worth while.

The

surface machining of the window includes the border around it.

There is also a compromise here: the sharp corners could be

better if a small end mill, a flat mill, was used all over,

but because the window is not normal to the z-axis, it won't

be sufficient anyway.

Look

at the screenshots to the left. A 2 mm endmill takes a round

after the milling with the 4 mm ball mill. There is a difference,

but it is not worth the trouble. It mainly creates new odd looking

surface details, because of the overlap between two geometrically

different tools

(screenshots

taken after completion of the whole truck, for clarity)

|

|

|

IMPORTANT

SURFACING PARAMETERS

In the first

operation, in the surface sequences, two very important parameters were

set. These two are not default:

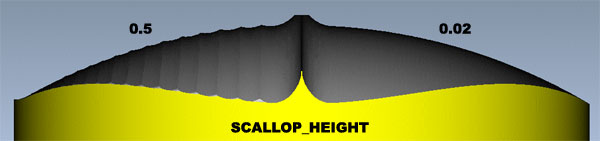

- SCALLOP_HEIGHT

- LACE_OPTION

To the right

is an explanation of both of them.

In your final

assignment, always use:

SCALLOP_HEIGHT

= 0.02

LACE_OPTION

= ARC / LINE CONNECT

|

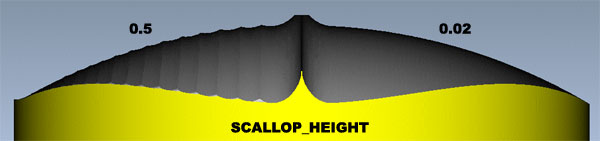

SCALLOP_HEIGHT

Scallop height determines the roughness of the surface. Smaller values

pull the toolpath closer together, making the overlap bigger and produces

a smoother surface. At the cost of time of course.

Scallop height determines the roughness of the surface. Smaller values

pull the toolpath closer together, making the overlap bigger and produces

a smoother surface. At the cost of time of course.

LACE_OPTION

|

|

|

In surface

milling, the tool can either mill in one direction or in zigzag moves,

connected with straight lines or arcs.

Zigzag

is fastest, with as few retracts as possible, while answering NO makes

the tool retract after each pass, starting from the same side every

time. See animations to the right. |

|

|

5. CREATING

A NEW OPERATION

OPERATION 2

To continue

the milling on the left side of the truck, a new operation is set up,

with the Reference Machine Zero placed as shown in Operation

2, i.e on the opposite side of the workpiece.

The

milling sequences should be identical to those on the right side.

Volumes and

parameters can be copied from earlier operations/sequences. As the two

sides are identical, this makes sense. See

the menus to the right.

Watch the

machining of the left side by clicking on the movie.

|

|

|

6. BOTTOM

SIDE OF TRUCK

OPERATION 3

The engraving

- sequence 3 - is not included in the video.

Parameters

different from the default milling parameters are listed.

| OPERATION

3 |

| Sequence

1 - Volume Milling - 10 mm end mill |

| |

Parameters:

Scantype = type_spiral

Rough_option = rough_&_prof |

| Sequence

2 - Surface Milling - 4 mm ball mill |

| |

|

| Sequence

3 - Engraving - 4 mm ball mill |

| |

Name

of creator

Parameters:

Groove_depth = 0.1 and 0.3 |

|

WATCH

VIDEO of OPERATION 3

|

|

Notes:

To machine the bottom in seq. 1, a volume is ceated that extends

well beyond the boundaries of the workpiece, to make sure all

of it is removed. The volume stops at the bottom of the truck.

In

the video you may notice that the tool enters the volume from

the side, instead of starting from the center. In

the video you may notice that the tool enters the volume from

the side, instead of starting from the center.

Entering side-ways is the best, and is always possible when

the volume is bigger than the workpiece, like in the picture

to the left. Some tool types can't drill - they have to enter

the workpiece horisontally.

See the menu to he right: Check Appr Walls and select the outer

vertical surfaces of the volume - the tool will now enter through

these "walls".

The

big surfaces of the tires have already been milled in Operation

1 & 2, therefore only the rounds on the tires are milled,

together with the axles, see animation to the left.

|

|

|

Engraving

following cosmetic Groove curves is very useful for engraving

small details or text onto the part. With the milling parameter

Groove_depth you can raise or lower the tool to a

desired height. No groove_depth value will make the tool

tip follow the curve at curve height.

The Groove feature is created in part mode, not in manufacturing

mode. Insert - Cosmetic - Groove

In

the animation above, groove_depth is just 0.1, meaning the

4 mm ball mill is lowered 0.1 mm into the bottom of the

truck, merely scratching the surface.

In the animation below, the groove_depth is 0.3, making

the engraving more visible

|

|

|

|

7.

NC CHECK

There are

two possibilities you should know about in NC Check simulation.

- How to

save an NC Check to be used as a starting point for another NC Check

- How to

simulate several sequences or operations

|

Saving

an NC Check Saving

an NC Check

Right after doing an NC Check, you can save the image, so you can

continue from that point in a later NC Check instead of starting from

scratch. Look at the image to the right: Save is only available after

NC Check, while restore is always available to retrieve a saved NC Check.

Save-Restore

was used in the videos of the six operations.

Simulate

several sequences or operations

When you want to do an NC Check of more than one sequence or operation,

the thing to do is to 'collect' a set of either sequences or operations

and save a CL (Cutter Location) file for this set.

Here is how

it is done:

- Select

CL Data - Output - Select Set - Create (name of set, accept default)

- (pick the sequences/operations to form the set) - select

the named set again - File - Done

- Play it:

CL Data - NC Check - Display - Filename (select file) - Run

|

|

8. LICENSE

PLATE, BACK END

OPERATION 4

Parameters

different from the default milling parameters are listed.

| OPERATION

4 |

| Sequence

1 - Volume Milling - 4 mm end mill |

| |

Definition

of volume: Window

Parameters:

Scantype = type_spiral

Rough_option = rough_&_prof |

| Sequence

2 - Surface Milling - 4 mm ball mill |

| |

Plate

finishing

Parameters:

Scallop_hght = 0.02

Lace_option = Line_connect

|

|

WATCH

VIDEO of OPERATION 4

|

|

Notes:

The first sequence is the volume milling. Here, the volume is

defined by a 2D sketch, called a Window.

The

simplest way to define geometry for a volume milling sequence

is by using a Mill Window, that is, by sketching or selecting

a closed contour in the retract plane. All surfaces visible

within the contour will be milled.

The

second sequence is surface milling, where the sides and bottom

of the cavity for the license plate are milled.

|

|

|

9. FRONT

END

OPERATION 5

Previous

sequences have already machined parts of the front. The focus now is on

finish machining the two large surfaces on the front and get nice sharp

edges wherever possible, to make the frontlights stand out.

The space is limited, so the 2 mm end mill will be used.

Parameters

different from the default milling parameters are listed.

| OPERATION

5 |

| Sequence

1 - Surface Milling - 4 mm end mill |

| |

Semi-finishing

of two front surfaces

Parameters:

Rough_Step_Depth = 3

Scallop_hght = 0.1

Prof_Stock_Allow = 0.1

Lace_option = Line_connect |

| Sequence

2 - Surface Milling - 2 mm end mill |

| |

Finishing

front surfaces

Parameters:

Scallop_hght = 0.02

Lace_option = Arc_connect

|

| Sequence

3 - Trajectory Milling - 2 mm end mill |

| |

Finishing

sharp edges

The

bottom edge of the frontlight is followed, and the cutting height

- the tip of the mill - is controlled by the angled, large surfaces:

|

|

WATCH

VIDEO of OPERATION 5

|

2

large surfaces

|

Notes:

Notice the parameters sequence 1. When you add a Rough Step

Depth, you will have more than one level of surface machining,

in this case there will be 3 mm between each level.

Because

the next tool is a 2 mm mill- a rather fragile tool - the semi-finishing

with the 4 mm end mill is necessary to clear the way first,

leaving only a small amount to be removed with the 2 mm end

mill.

|

|

The finishing sequences on the front and around the frontlights

is done with the same tool, a 2 mm end mill.

Normally,

surface machining of surfaces not normal to the z-axis are milled

with ball mills, but here it would leave some strange looking

edges.

The

2 mm end mill is used here because I want to avoid the problem

of strange geometry around the frontlights.

Had

the area on the front of the truck been larger, I might have created

additional sequences to spare my 2 mm - it should never do too

much work.

In this case, and because of the angled, but flat front surfaces,

it is OK. Front surfaces with curvature would force me to use

a ball mill. The result from an end mill would not be tolerable.

The

top animation shows what happens when using a ball mill and then

an end mill

The

bottom animation shows the case of the truck, where the same endmill

has been used for both the surface machining and the trajectory

finishing of the frontlight sides.

The

"end mill/end mill" solution gets closer to the model

geometry

|

|

|

|

|

10. FROM

THE TOP

OPERATION 6

Take a look

at the NC Check video first. Underneath is described the sequences in

this operation.

Parameters

different from the default milling parameters are listed.

| OPERATION

6 |

| Sequence

1 - Volume Milling - 10 mm end mill |

| |

Parameters:

Scantype = type_spiral

Rough_option = rough_&_prof |

| Sequence

2 - Surface Milling - 10 mm ball mill |

| |

Finishing

Parameters:

Scallop_hght = 0.02

Lace_option = Line_connect

|

| Sequence

3 - Volume Milling - 4 mm end mill |

| |

Parameters:

Scantype = type_spiral

Rough_option = rough_only |

| Sequence

4 - Surface Milling - 4 mm ball mill |

| |

Finishing

of front window and storage compartment

Parameters:

Scallop_hght = 0.02

Lace_option = arc_connect |

|

WATCH

VIDEO of OPERATION 6

|

No

surfaces excluded from profiling

Several

surfaces excluded from profiling, fx. on the front and on the

motor helmet

|

Notes:

At

this point I want to introduce a time saving feature. Not time

saving for the programmer, but in the workshop, milling the

part: Excluding surfaces from profiling (found on Seq

Setup menu, shown to the right) At

this point I want to introduce a time saving feature. Not time

saving for the programmer, but in the workshop, milling the

part: Excluding surfaces from profiling (found on Seq

Setup menu, shown to the right)

When

you do a volume milling sequence, with the parameter Rough_option

set to rough_&_profile it means that for each

machining level, there will be a profiling pass, meaning a finishing

pass on all surfaces of the volume. Most of the time, this is

OK, but on surfaces, where you plan to do a surface milling

sequence later, the profiling pass might leave small lines,

visible after the surface milling sequence, look at the two

pictures to the left.

They

are in theory non existing, but volume milling is a roughing

process, where the tool remove a great amount of material, causing

vibrations. These vibrations may lead to unstability, causing

the tool to go a little closer than it was meant to.

Another

thing is that profiling the outer surfaces of the volume is

a complete waste of time, because they lie beyond the workpiece

boundaries. It won't do any harm, but it takes extra time.

Look

at the image below, these vertical meshed surfaces of

the volume should be excluded from profiling.

|

|

|

|

|

Comments

to the storage compartment in the back of the truck:

After

the first volume milling sequence, a fairly large amount of material

is not milled away, because the 10 mm is too big. Therefore a

small volume is created, to be used in sequence 3 with a 4 mm

end mill.

The

'floor' is not milled in any of the volume sequences, because

a uniform machining with one tool type is desired. Because of

the corner radiuses on the floor of the storage compartment, the

only tool usable is the 4 mm ball mill. The 10 mm end mill would

avoid the rounds and create a step instead.

The

vertical sharp corners of the compartment are not vital for the

look of the truck, so no effort is made especially to make them

sharper, i.e by using a smaller tool.

|

End

of case study

|

This case study will help you when you do your final assignment in CAM.

From the exercises you will know what fx. volume, profile and surface

milling is about, but when it is best to use which

method takes a lot of experience. Spend about 30 minutes to read

this study.

This case study will help you when you do your final assignment in CAM.

From the exercises you will know what fx. volume, profile and surface

milling is about, but when it is best to use which

method takes a lot of experience. Spend about 30 minutes to read

this study.

Scallop height determines the roughness of the surface. Smaller values

pull the toolpath closer together, making the overlap bigger and produces

a smoother surface. At the cost of time of course.

Scallop height determines the roughness of the surface. Smaller values

pull the toolpath closer together, making the overlap bigger and produces

a smoother surface. At the cost of time of course.

In

the video you may notice that the tool enters the volume from

the side, instead of starting from the center.

In

the video you may notice that the tool enters the volume from

the side, instead of starting from the center.

Saving

an NC Check

Saving

an NC Check

At

this point I want to introduce a time saving feature. Not time

saving for the programmer, but in the workshop, milling the

part: Excluding surfaces from profiling (found on Seq

Setup menu, shown to the right)

At

this point I want to introduce a time saving feature. Not time

saving for the programmer, but in the workshop, milling the

part: Excluding surfaces from profiling (found on Seq

Setup menu, shown to the right)